Model:

Your Model No.:

Mfr. Model No.:

Threadlockers are designed to lock fasteners in place while sealing them against wear and tear. Suited for a wide range of applications, LOCTITE® Threadlockers increase the reliability of threaded assemblies. The below selection guide will help you find the right Threadlocker for your application.

Increased friction reduces clamp load; will not ensure reliable threadlocking under dynamic loads.

Expensive and time-consuming methods, they often impose challenges to line up their components appropriately (i.e., tabs, cotter pins).

Prevent self-loosening, but are expensive; need larger flange-bearing surfaces and may damage the surfaces.

More expensive than a standard nut, nylon inserts increase friction, which results in inaccurate torque.

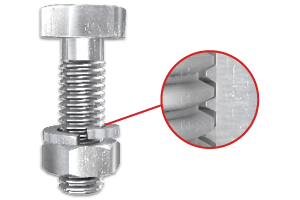

Without Threadlockers:

Vibrational loosening due

to 85% air gap.

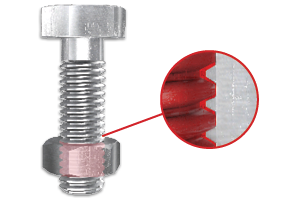

With Threadlockers:

There's no vibrational

loosening and no gaps.

Suited for a wide range of applications, LOCTITE® Threadlockers increase the reliability of threaded assemblies.

Max quantity is 999999999. Your cart item has been updated

Model:

Your Model No.:

Mfr. Model No.:

Qty.: