Model:

Your Model No.:

Mfr. Model No.:

Once you have selected the correct ladder for the job, it should be carefully inspected before each set-up and use. NEVER USE A DAMAGED LADDER. Many incidents are caused by the use of damaged or otherwise unsafe ladders, and result in severe injury or death.

Please refer to the inspection procedure and form for a full outline of what to look for when inspecting your ladder(s). This outline includes the following key warning signs:

Fibreglass ladders are non-conductive, strong and durable. Fibreglass rails are manufactured in a process called pultrusion, wherein continuous strands and mats of glass are encapsulated in thermoset resin and molded into a variety of rail profiles. The resin incorporates colour pigments and UV inhibitors. The UV inhibitors protect the resin from surface UV and atmospheric corrosion. On average every 3-5 years, depending on exposure of the ladder to direct sun, and atmospheric pollutants, the surface of the fibreglass should be checked for “fibre prominence” as may be witnessed by a rough feel when you run your hand across it. If prominence is noted, the ladder rails should be lightly “sanded” using a nonabrasive ScotchBrite® scouring pad, solvent-cleaned then “painted” with a brush-applied, transparent, 2-part polyurethane coating. (i.e. Sherwin-Williams #RS 6010 clear enamel with #RS 9820 hardener). This coating will provide further UV, and atmospheric corrosion protection, and should last for at least another 3-5 years.

Despite their strength and durability, fibreglass ladders can be broken, cracked, gouged or punctured if not protected from damage, or used improperly. Fibreglass ladders should be carefully inspected, before each use, for the following defects:

A see-through separation of the fibreglass laminations visible from both sides. The ladder should be removed from service until the rail can be replaced or the ladder disposed of.

A separation of material, not visible from the other side. The ladder should be regularly and carefully inspected to ensure it does not deteriorate further. If moisture is allowed to penetrate the rail, the non-conductive properties are greatly reduced.

To reduce the risk of water penetration, clean the area with a mild solvent solution, and apply a polyurethane clear-coat.

A surface crack that does not penetrate the laminate layer. Inspect regularly to ensure it has not expanded, especially into the laminate area. If moisture is allowed to penetrate, the non-conductive properties of the rail are greatly reduced. A polyurethane clear-coat or an exterior quality paste wax may be applied to inhibit moisture penetration.

A puncture that is visible from both sides. The ladder should be removed from service until the rail can be replaced or the ladder disposed of.

Like any equipment, your ladder requires periodic preventive maintenance.

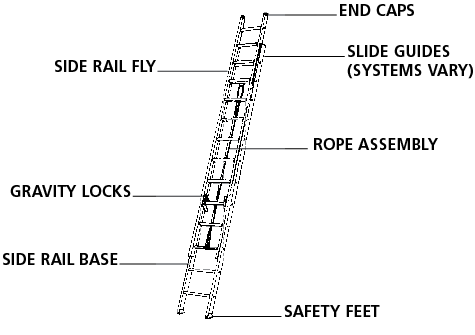

The entire ladder should be cleaned on a regular basis and moving parts should be kept clean and lightly lubricated. Slide guides and safety feet should be replaced if worn and the rope assembly replaced at least once a year. In order to maintain the maximum dielectric properties of fibreglass ladders, they should be regularly cleaned with mild detergent and water and waxed with an exterior quality paste wax. The wax helps to keep water and dirt out of scratches and gouges that might otherwise reduce surface dielectric properties.

Ladder Repair

There are only a few ladder components that can be repaired in the field. It is very important that replacement parts are properly installed on your ladder. An incorrectly installed part is as dangerous as a broken or worn out one. In most cases parts can be replaced with the self-locking nuts, bolts and washers; however, in some instances riveting is required.

If in doubt, check with a TENAQUIP Ladder Specialist.

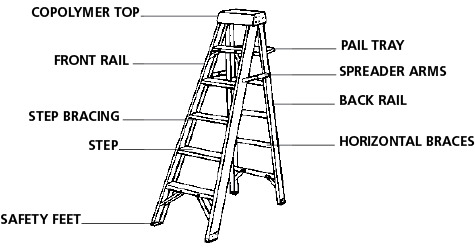

The following is a list of the most common parts that can be replaced by a competent maintenance professional:

| Extension Ladder |

| Safety Feet |

| Rope Assembly |

| Rung Locks |

| Slide Guides |

| Protective End Caps |

| Cog Wheels |

| Pail Tray |

| Step Ladder |

| Safety Feet |

| Spreader Arms |

| Head Tray |

| Pail Tray |

Ladder Replacement

The simple rule “if in doubt tag it out” applies when a ladder has been damaged badly enough to break, bend, or twist parts. Tag it out-of-service until it can be repaired by a competent technician, or disposed of.

Assign responsibility: It is important to the success of your program to assign responsibility, give authority and hold someone accountable for the program. This person should typically be someone in a supervisory, maintenance, or health and safety related role in the workplace.

Set up a control manual: In order to do this you will need to take an inventory of your ladders and give each a permanent identification number. Determine the frequency of use of each ladder and with this information, set up the appropriate inspection frequency for each ladder.

Inspect ladders: A thorough inspection of each ladder should be carried out. Those that require repair or replacement should be immediately tagged DO NOT USE. These items should be logged in the control manual indicating: the nature of the problem; the individual responsible for corrective action and the due date for repair or replacement.

Follow up: Upon completion of repair, the control manual log entry should be signed by the person responsible for the repair, and the supervisor accepting the ladder ready for use (a maintenance work order system works well in this situation).

NOTE: A formal ladder control program still requires the user to complete an inspection before each first use of the ladder.

See the Ladder Inspection Form.

Max quantity is 999999999. Your cart item has been updated

Model:

Your Model No.:

Mfr. Model No.:

Qty.: