Model:

Your Model No.:

Mfr. Model No.:

The ANSI cut standard uses a razor blade in its testing method to determine the weight in grams needed to cut through the material of the glove using linear motion. A cut level is then assigned to the gloves material, determined by the range of weight used during testing.

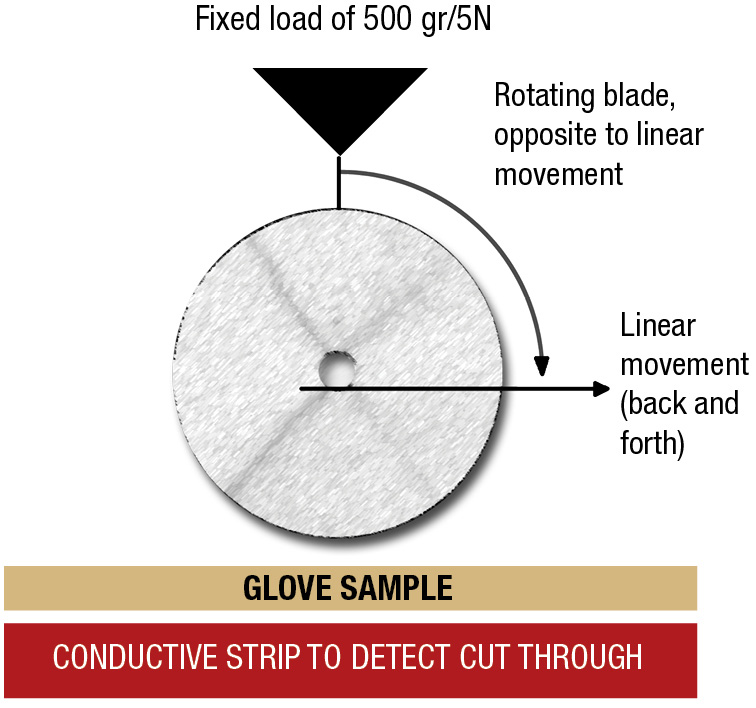

The EN 388 cut standard uses a circular blade, under a fixed load, in its testing method to determine the blade rotations needed to cut through the material of the glove. A cut level is then assigned to the gloves material, determined by the number of blade rotations used during testing. Additionally, a cut test using a TDM 100 cut test machine is also performed. This test, measured in Newtons, will measure the cut resistance with a straight blade. This will add an additional 6 levels to the cut rate standard, which are represented by letters A to F.

| Cut Level | Weight (G) Needed to cut with 1" (25mm) blade travel | Average cut index (10 measurements) |

|---|---|---|

| 0 | <119 | <1.2 |

| 1 | 12-249 | 1.2-2.4 |

| 2 | 250-499 | 2.5-4.9 |

| 3 | 500-999 | 5.0-9.9 |

| 4 | 1000-1999 | 10.0-19.9 |

| 5 | >2000 | >20 |

2 Newtons

(203 grams)

5 Newtons

(509 grams)

10 Newtons

(1019 grams)

2 Newtons

(203 grams)

5 Newtons

(509 grams)

10 Newtons

(1019 grams)

ANSI/ISEA105-15

EN 388:NEW

Max quantity is 999999999. Your cart item has been updated

Model:

Your Model No.:

Mfr. Model No.:

Qty.: